Our management is committed to provide the best customer service. The sales department has a very clear objective… “Make sure to do the impossible to satisfy our customer.” This is achieved through our personalized service using the Company’s resources helping you to manage your project effectively.

At Rapid, we live and breathe customer satisfaction. Each of our valued customers is assigned a dedicated account/program manager who takes personal ownership of their unique requirements. We don’t just address special inquiries, order acknowledgments, and rescheduling; we infuse every interaction with passion and a commitment to excellence. We pride ourselves on our ability to adapt, ensuring that our services and systems evolve to meet the ever-changing needs of our cherished clients.

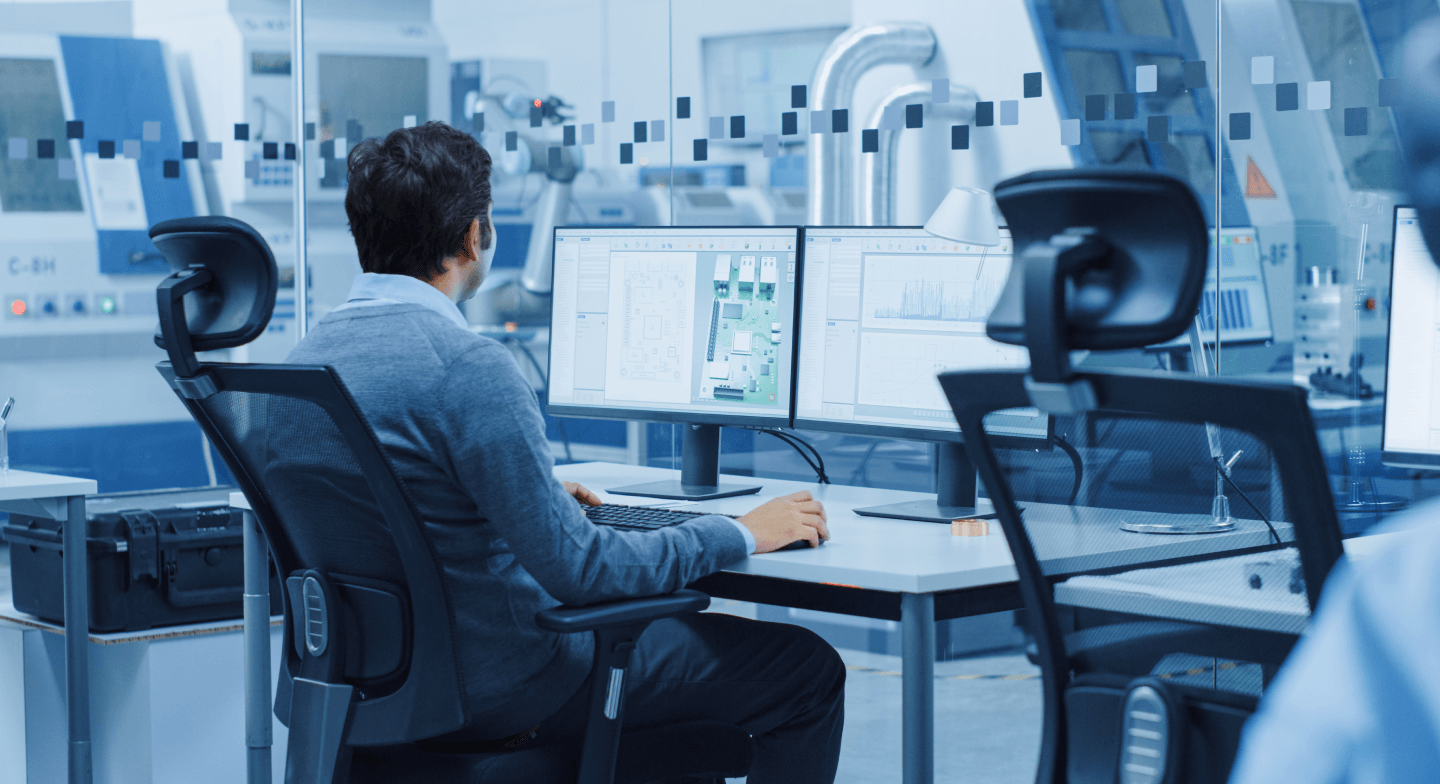

We conceive and understand your requirements, providing design and drawing support to initiate the quote process.

We are committed to delivering a competitive quote on time, offering AVL options and secondary sources for cost efficiency.

Our NPI team, an extension of your Engineering team, is dedicated to supporting you. With experienced staff, we ensure the delivery of your Rapid Prototype Material (RPM) within the shortest CT.

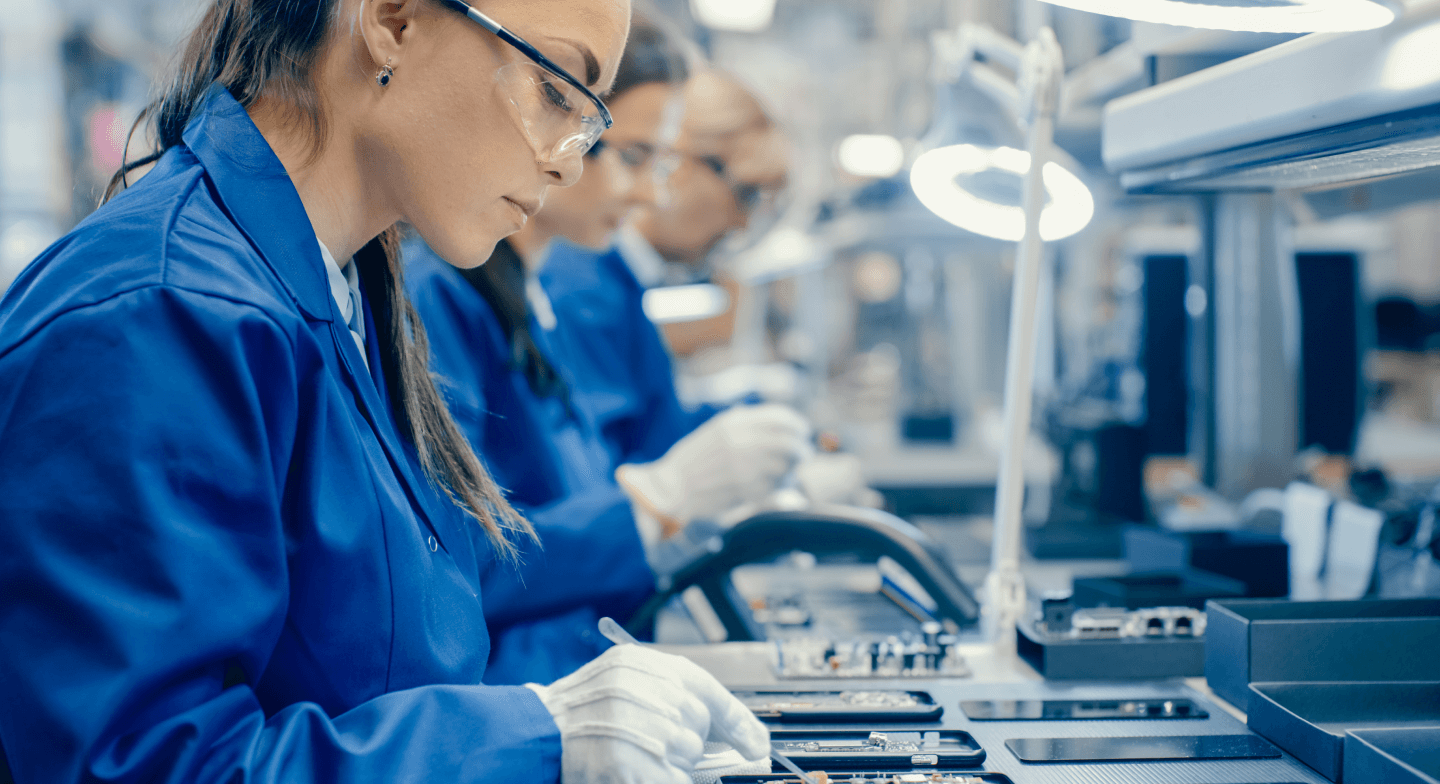

We ensure the efficient manufacturing of a high volume of products to meet market demand. This involves optimizing the supply chain, ensuring quality control, achieving cost efficiency, implementing effective logistics, and continuously improving for scalability and regulatory compliance. The focus is on large-scale production to deliver products to the market efficiently.

Program managers work closely with you to understand project/product EOL time frame, minimizing inventory levels and costs.

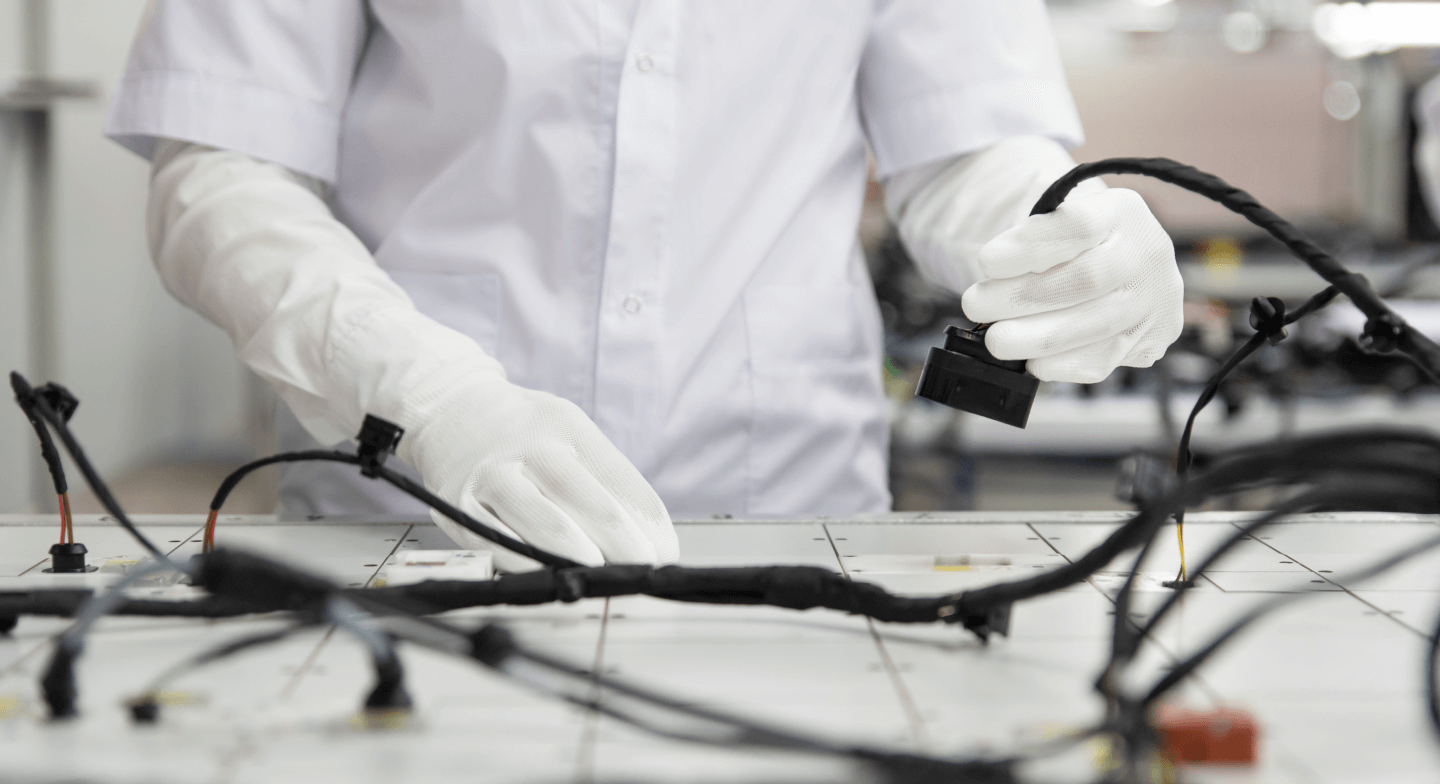

Continual improvement of processes and performance is a permanent objective of the Rapid Manufacturing organization. Rapid team will assess your project for areas of cost savings or efficiencies. Some of the tactics that have been put in placed with our customers:

Cable bundling analysis to reduce cycle time, improve efficiency and costs.

Raw material review with customer engineering material team to identify and implement cost saving solutions.

In house alternative source pre-qualification process

Raw material review with customer engineering material team to identify and implement cost saving solutions.

Tailored “migration plan” to Rapid low cost region factories to support transfers and higher volume builds, along with cost down solution.

150+ years of experience solving interconnect challenges and enhancing product time-to-market with design and engineering support.

Material experts streamline supply chain, emphasize just-in-time inventory, minimizing lead times, reducing costs, and optimizing production flow.

Customer-centric wire harnesses, electro-mechanical assemblies, and box builds, offering quality and cost-effective solutions.

Quality is paramount at Rapid Manufacturing. We surpass expectations with skilled personnel, rigorous practices, and cutting-edge equipment.

Customer Support