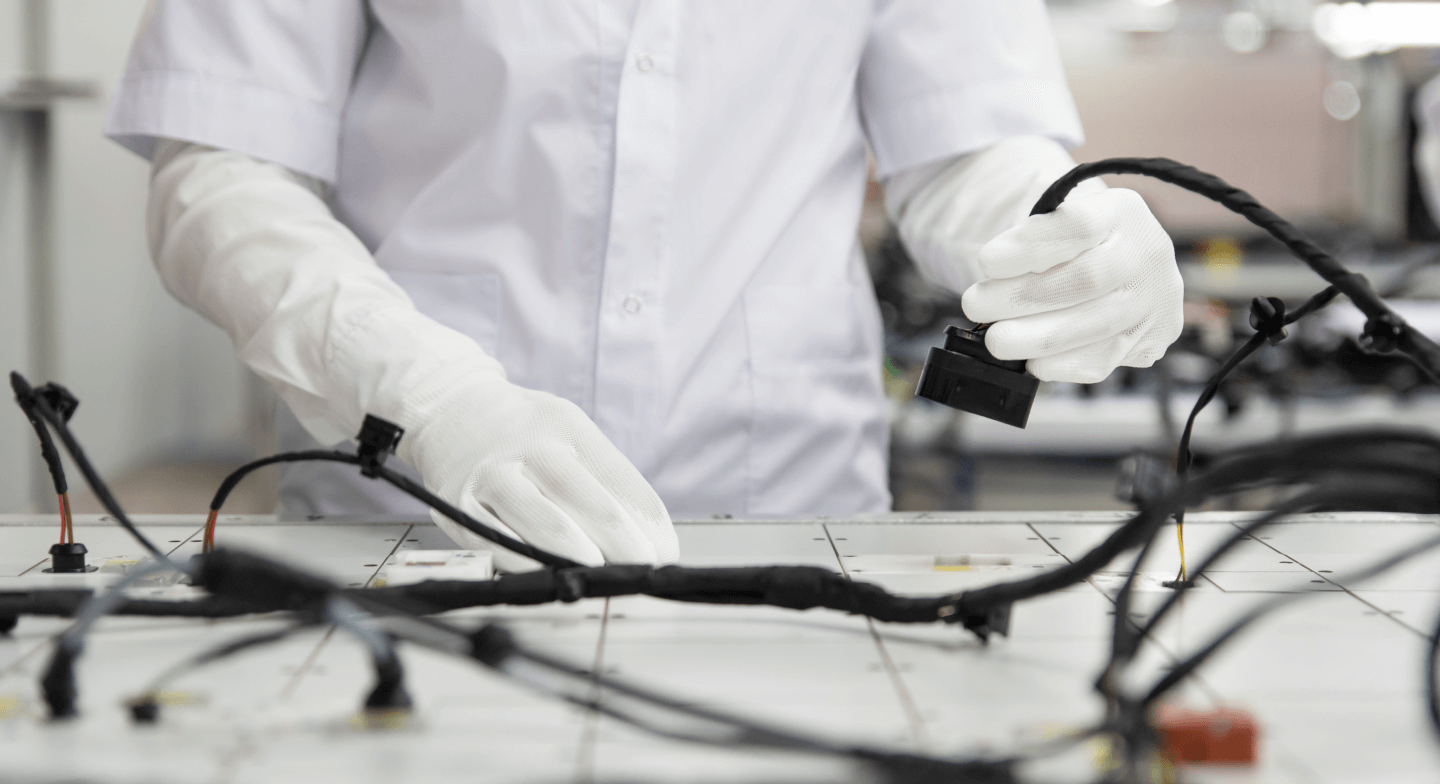

Crafting wire assemblies, from simple cut wires to intricate assemblies with hundreds of discrete points. Our efficient and precise processes cover crimped or soldered connections using various cable types – round, shielded, flat, coax, and more – for power, control, communication, and data transfer. Specializing in soldered, crimped, and mass terminations.

Specializing in pneumatic interconnections, we offer customer pneumatic tube assemblies with materials like vinyl, Teflon, PVC, etc. We cover wire gauges from 2AWG to 32AWG, conducting precise pull testing, crimp height evaluations, and Leak test.

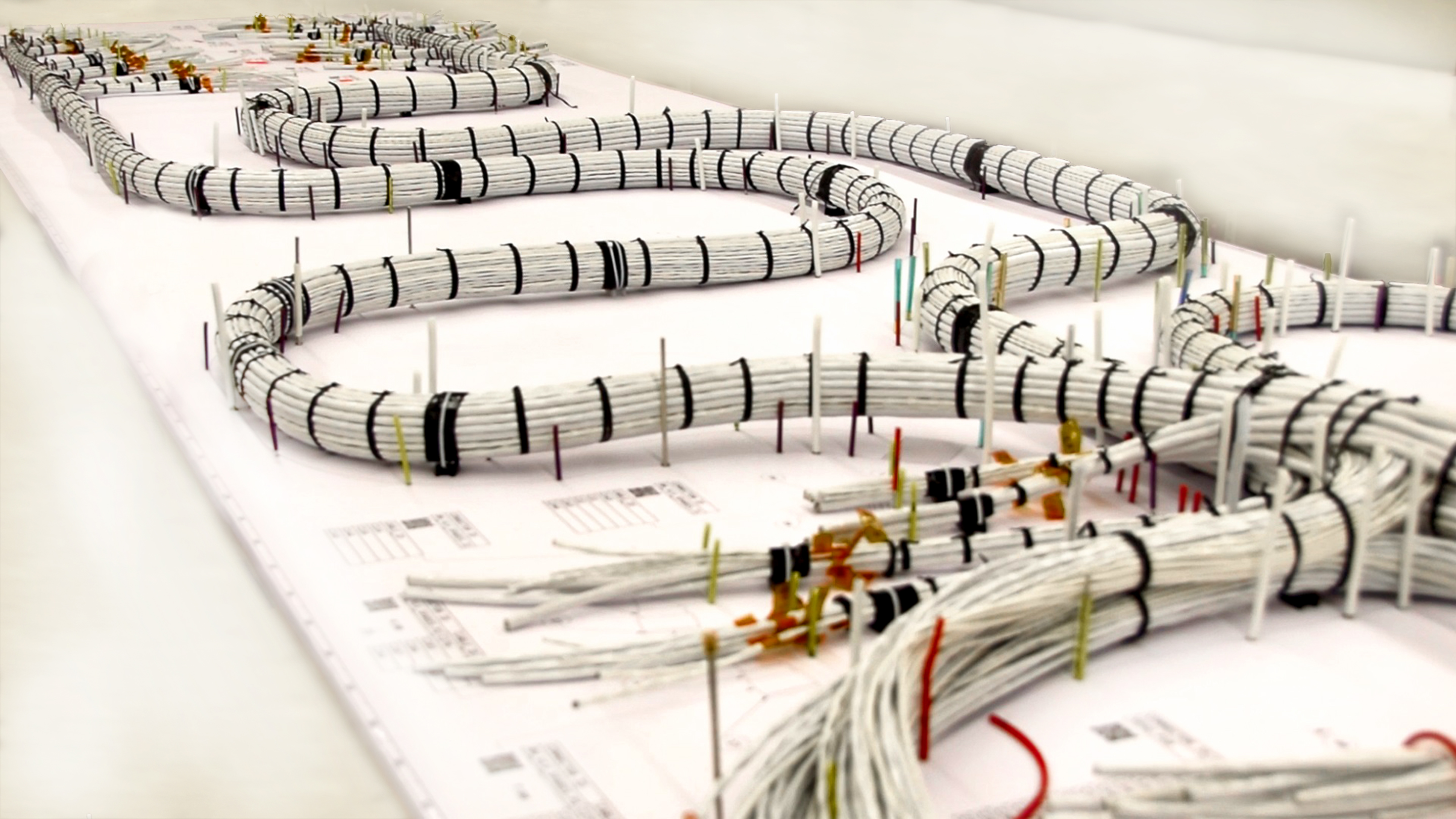

Wire/Cable harnesses with fully terminated ends, connectors, lugs and terminal blocks, Rapid ensures precision in fit and routing on custom harness boards. Our one-stop ‘drop in’ harness, incorporating multiple cable assemblies, streamlines system-level assembly. By bundling power, video, communication, and control cables on a custom board with labeled connection points.

Our molding facility features a 20-ton injection molding press, specialising in over-molded cable assemblies. We customize molds with multiple cavities, catering to a diverse product range to meet specific customer requirements.

We specialize in the meticulous assembly of cables integrated with various passive electronic components, including fans, stepper motors, sensors, and transformers.

Our extensive range of Fiber Optic products designed to support the Broadcast and Data Infrastructure market sectors. Our offerings include data switches, optical module transceivers, modems, and broadcaster equipment.

Our extensive range of Fiber Optic products designed to support the Broadcast and Data Infrastructure market sectors. Our offerings include data switches, optical module transceivers, modems and broadcaster equipment.

Advanced prototyping services translate your concepts into tangible models, accelerating your design iteration cycle.

Rapid builds functional prototypes that mimic real-world performance, validating your concept before full-scale production.

Ensuring flawless performance of your electronics with in-depth electrical testing throughout the manufacturing process.

Rapid subjects your products to simulated real-world conditions, guaranteeing they perform under pressure.

Wire or cable assemblies including fans, power supplies, transformers, passive components, motors and sensors. Rapid has the expertise to properly handle and terminate these components as well as develop custom functional testing programs when required.

Vertically integrate your supply line by allowing Rapid to assemble the wire and cable harnesses into the box or chassis for you; save time, reduce inventory, overhead and cycle time on your production floor. Using consigned or turnkey chassis Rapid can bring smart integration to your supply line.

Let Rapid take our chassis wiring service to the next level and install your system components into the box as well. Power transformers, Terminal blocks, PLC’s, or switches. Rapid has the experience to be your higher level equipment manufacturer.

Quality is paramount at Rapid Manufacturing. We surpass expectations with skilled personnel, rigorous practices, and cutting-edge equipment.

With global strategic locations we are able to support our partnered customers in every region of the world.

Global ERP system coordinates resources, with IT as a key pillar supporting customers and enhancing competitiveness.

Management prioritizes superior customer service; sales aims to ‘achieve the impossible’ through personalized service and resourceful solutions.

Customer Support